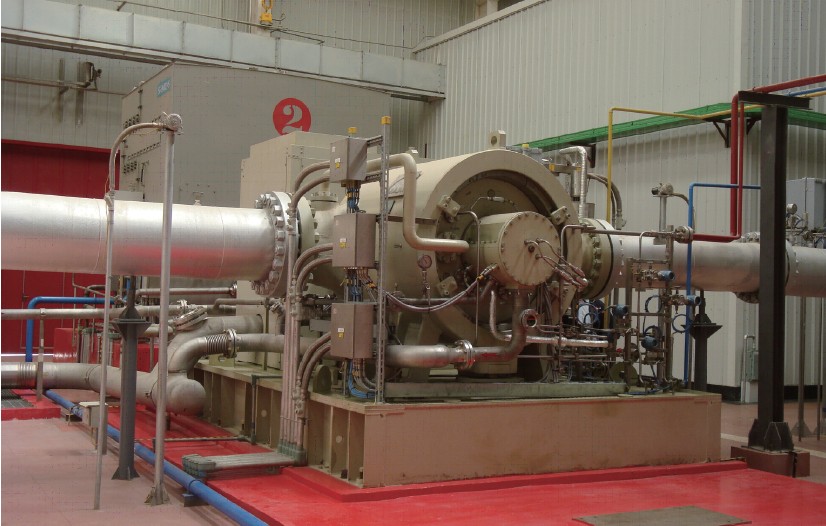

On-site Services:

Installation and Commissioning:

·Arrival inspection,hoisting guide,coarse alignment,pipeline installation guide and control system detection.

Routine maintenance:

·Compression unit Ia(4000 hrs) level maintenance

·Assist system filter replacement;Probe detection;Motor grease;Check vibration probe;Conduct oil test.

·Compression unit Ib(8000 hrs) level maintenance Contents in Ia level maintenance are included

Optimizing performance:

·Component upgrade and system optimization

Troubleshooting:

·Fault analysis,debugging and replace for various sensors.

Warehouse management:

·Quantity control for the maintenance spare parts.

Maintenance:

·Compression unit II(24000 hrs) level maintenance

·Contents in Ib level maintenance are included;Replace dry gas seal;Check compressor bearing;

Replace gas generator.

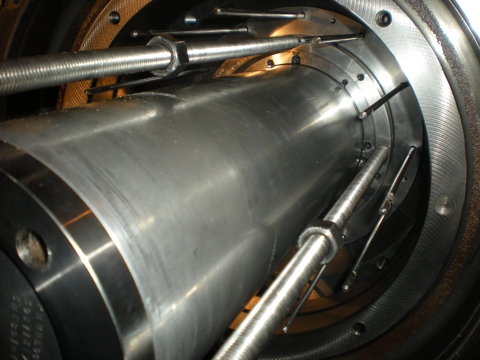

·Compression unit III(48000 hrs) level maintenance

·Contents in II level maintenance are included;Replace the power turbine bearing;Disassembly inspection for compressor.

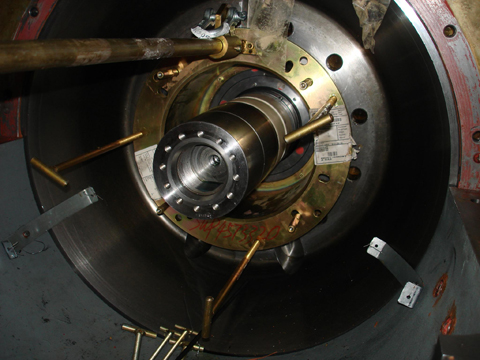

Replace GE dry gas seal unitv

Replace the auxiliary seal of RR compressor